Saturday, December 23, 2006

Sunday, December 17, 2006

Sunday, December 10, 2006

An e-petition has been lodged at No.10, requesting the PM to:

Saturday, December 02, 2006

Monday, November 27, 2006

Friday, November 24, 2006

Wednesday, November 22, 2006

Tuesday, November 21, 2006

Thursday, November 16, 2006

Wednesday, November 15, 2006

1 Nov 2006

Dodging the actual question, the minister refers instead to the other, former, evidence, which was presented during the 2004 formal investigation, and which, he states, was scrutinised by leading experts*.

* As a matter of interest, it should be explained that the evidence that was admitted during the 2004 formal investigation was collected and reviewed by the Treasury Solicitor (who acted under instructions from the Attorney General) prior to being brought to the attention of the retained experts.

Tuesday, November 14, 2006

We have recently received an emailed reply from the Department for Transport (DfT):

http://www.freewebs.com/inconvenientcitizen/dftletter7nov.htm

The paper is detailed; it includes pictorial explanations and evidence of shortfalls in the RFI.

269.—(1) Where a formal investigation has been held under section 268 the Secretary of State may order the whole or part of the case to be re-heard, and shall do so—

(a) if new and important evidence which could not be produced at the investigation has been discovered; or

(b) if there appear to the Secretary of State to be other grounds for suspecting that a miscarriage of justice may have occurred.

Sunday, November 12, 2006

1 November 2006

Wednesday, November 08, 2006

The Arab was sold in 1983 and converted into a support depot ship for submersibles; in 1984 it was converted back into a stern trawler. The vessel continued to work as a stern trawler until early 2006 when it was converted into a fish factory ship.

Tuesday, November 07, 2006

Wednesday, November 01, 2006

Whilst in other cases the MAIB would collect evidence and provide analysis on the causes and circumstances of a marine accident, in the Gaul case, I am told, the MAIB provided the documentary evidence, but left the government’s retained experts to formulate their own conclusions. The MAIB, my interlocutor said, was in a difficult situation vis-á- vis the Gaul case.

Saturday, October 28, 2006

No adjustment has been made for 2006 prices.

Gadfly: Perhaps Dr Ladyman should know that the Original Formal Investigation was concluded in 1974.

There appear to be some items missing from the above list. The total costs to the Department should also have included:

1. the costs of the stability and seakeeping investigations and model tests carried out for the Department by NMI and YARD between 1975 and 1978 estimated at £75,000 (in 1976 prices)

2. the costs of the two reports by Roger Clarke published in 2000. Stated to have cost the Department £50,000 at that time

3. additionally, the costs of 32 years of governmental time that has not been included in the above (political staff, technical, clerical and administrative staff, MOD, legal etc) - £1m at todays prices would not be an unreasonable evaluation!

If a simple compound interest calculation is carried out on the costs detailed above, using historical Bank Rate indices, then a figure of £10m at 2006 prices is obtained!

Sandra Gidley: To ask the Secretary of State for Transport what progress has been made towards the implementation of the formal safety recommendations arising from the F. V. Gaul Re-opened Formal Investigation. [96790]

Dr. Ladyman: It is considered that, as far as is reasonably practicable, the recommendations have been implemented.

Gadfly: The four formal safety recommendations have not been implemented.

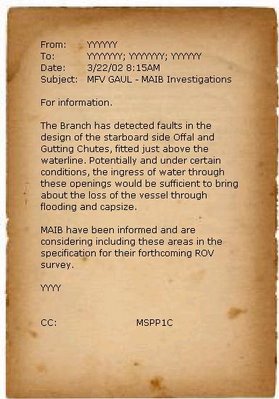

Sandra Gidley: To ask the Secretary of State for Transport whether any evidence of a design fault in the construction and arrangement of the duff and offal chutes on the trawler F. V. Gaul was made available to the Wreck Commissioner during the 2004 investigation. [96794]

Dr. Ladyman: The Marine Accident Investigation Branch provided the inquiry with a copy of a full set of technical drawings for the vessel, a number of which detailed the design of these chutes. These drawings were reviewed by the technical experts and the expert representing the Department for Transport referred to these drawings in the production of the document “Notes on the duff and offal chutes”, submitted to the Re-opened Formal Investigation. These notes included comments on the design of the chutes and the potential design inadequacies.

Gadfly: First of all, the question that had been asked was not answered (i.e. was any evidence of a design fault made available to the Wreck Commissioner?). A yes or no answer would have sufficed.

Secondly, The Marine Accident Investigation Branch would provide, as they normally do and as the Treasury Solicitor recently confessed, “considerable assistance” to the Wreck Commissioner. They would therefore provide much more than a set of old drawings.

Thirdly, the “Notes on the duff and offal chutes”, only commented on a presumed design deficiency in relation to the difficulty of maintenance of the non-return flaps.So, in a couple of sentences, Dr Ladyman implies that either the MAIB performance was poor, or the MAIB witheld evidence, or the retained experts were unable to recognize an obvious design fault in the construction and arrangement of the duff and offal chutes.

***

“When you hear a denial of knowledge or responsibility, rate it carefully on the plausibility scale. The real culprit is usually at the top, as his nose will eventually demonstrate”. (Patrick Brown, 1999, Plausibility and Pinocchio)

Thursday, October 26, 2006

Thursday, October 19, 2006

Tuesday, October 17, 2006

Sunday, October 15, 2006

In a recent message, the Treasury Solicitor writes: “You have indicated that in your view the chutes were a design fault. This is your view but appears not to have been accepted as such by any of the retained experts.”

(2) Concluding remarks from Mr Meeson (Investigation transcript) suggesting answers to the formal questions:

“………Although the design of the non-return flap was deficient, in that it was liable to seize over time and had no real means whereby it could be maintained, proper use……..”

(3) This was also questioned in the technical report published on our website: http://www.freewebs.com/inconvenientcitizen/fulltechnicalreportpdf.htm.

Saturday, October 14, 2006

Wednesday, October 11, 2006

As I write these lines, Mr Laurance O'Dea (the Treasury Solicitor) is investigating.

As I write these lines, Mr Laurance O'Dea (the Treasury Solicitor) is investigating.Why did this not happen during the 2004 formal investigation is something that may also be worth investigating.

Anyway, we hope that, this time round, our concerns will receive due attention and we wish Mr Laurance O'Dea good luck.

Monday, October 02, 2006

Saturday, September 30, 2006

Monday, September 25, 2006

Reprisals

Sunday, September 17, 2006

(!)

Friday, September 15, 2006

Thursday, August 31, 2006

- That the Gaul capsized and sank in severe weather following undetected seawater ingress into the factory space. The water entered this space through two hull side chute openings[1].

- That each of these two hull side chute openings had two means of closure: an outer non-return flap valve and a hinged inner cover; and that both of these closures were open prior to, and during the loss of the vessel.

- That, as a result of inadequate shore-side maintenance, both outer flap valves had become seized in the open position due to corrosion in their hinges, and that they had been in this condition since the time of the vessel’s departure from Hull, 16 days prior to the accident;

- That the hinged inner covers had been left open and unsecured by the crew; and

- That, had the crew closed the inner covers, this would have been sufficient to prevent the loss of the vessel.

In such circumstancess, if the inner covers had also been open or had subsequently failed[2] , the seawater would have been able to enter the vessel unhindered.

1. When defining the scope of ship classification, the formal report failed to include the Classification Societies’ responsibility for watertight integrity. The definition within the report reads:

While the definition as per IACS – Quality management System requirements manual states in respect of “Classification service” point 1. that “The structural strength (and where necessary the watertight integrity of) all essential parts of the exterior boundaries of the ship or offshore installation and its appendages.”

2. The definitions provided in the formal report for weathertight and watertight properties read as follows:

“Watertight – impervious to the passage of water, as applied to ship’s structure, closures and joints. A watertight opening is so constructed that when closed, it will prevent water under pressure from passing through, and normally incorporates a gasket.”

“Weathertight – capable of being sealed to exclude water in normal sea conditions. A weathertight opening is typically designed to keep out rain and spray only.”

“Watertight means capable of preventing the passage of water through the structure in either direction with a proper margin of resistance under the pressure due to the maximum head of water, which it might have to sustain.” “Weathertight means that in any sea conditions water will not penetrate into the ship.”

(SOLAS 1974 as amended, 1966 Load Line Convention and Torremolinos Convention 1977)

Thus, a weathertight fitting should be designed to withstand, in any sea conditions, water pressure and prevent the passage of water from one side only.

A watertight fitting, on the other hand, must, when closed, prevent the passage of water through an opening no matter which side is under pressure.

The principle shortfall in the strength of the chute’s inner covers is related to their direction of opening when considered in conjunction with external sea pressure loading (full sea loading on the covers would only be resisted by 3 butterfly nuts, instead of the overlapped gasketed steel plating arrangement that is normally associated with a weathertight joint).

3. It is also stated in the report that: “it is not clear how the spindle could have been repaired or replaced should the need arise without burning off the balance weight from the connecting arms”However, the construction drawings for the duff and offal chutes show quite clearly that the hinge, spindle, balance weight and connecting arms can be readily dismantled for maintenance, repairs or replacements. (?!)

(a) in respect of claims for loss of life or personal injury,

(i) 2 million Units of Account for a ship with a tonnage not exceeding 2,000 tons,”

This would amount today to approx. 3m USD per life lost (1 SDR = 1.48727 USD)

For those who wish to read the full technical argument behind the above points, please visit this link